At Jan Kemp BV, we are proud to be exclusive dealers of the high-quality

magnet systems from KW Generator, an innovative company from Germany pioneering unique systems. We supply and install the GEMA Industrial magnetic systems. This is the solution for steel mills and mobile excavators. These high-quality systems combine maximum reliability with ease of use and low maintenance costs.

GEMA Industrial: flexible magnet solutions

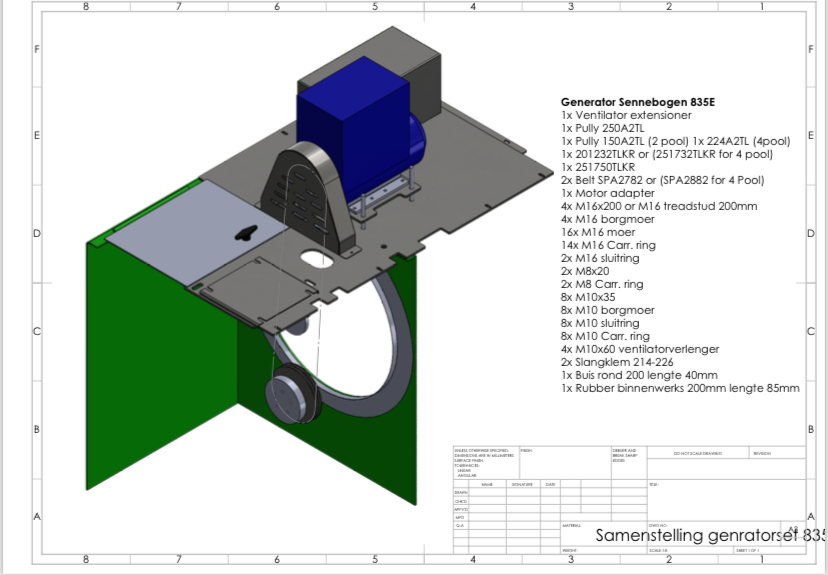

The GEMA Industrial series (10, 15, 20 and 30 kW) is designed as a compact, complete control system for magnetic plates. A key advantage of this system is that the generator can be driven in two ways: by hydraulic power or via a V-belt. This makes it flexible for different machines and working environments.

Why we often choose a V-belt

Although both drive methods are reliable, at Jan Kemp BV we often opt for a V-belt. In this case, the machine's motor drives a generator via a V-belt. The mechanical rotation is converted into electricity for the magnet. We prefer a V-belt for several reasons:

- Lower maintenance costs: a V-belt has fewer moving parts and is easier to replace than hydraulic components.

- Less risk of breakdowns: no risk of hydraulic leaks, keeping the machine cleaner and reducing downtime.

- Cost savings: installation and replacement of a V-belt are usually cheaper than hydraulic repairs.

- Easy integration: V-belt drives can often be fitted more quickly and without major modifications.

Advantages of the GEMA Industrial system

- Compact and complete: all components for controlling magnetic plates are integrated in one unit.

- Reliable operation: the system continuously monitors voltage, current and status of the magnet, preventing malfunctions early.

- Flexible control: multiple magnetic plates can be operated separately or in groups, ideal for complex applications.

- Battery backup: integrated management ensures that the magnet continues to function reliably even in the event of a power failure.

Why choose Jan Kemp BV?

With years of experience in transfer machines and magnet systems, we offer production, delivery as well as full service from advice to installation and maintenance. As an exclusive dealer of KW Generator, we guarantee high-quality German technology, combined with local expertise and fast support. The benefits at a glance:

- Choice of hydraulic or V-belt drive.

- Tailored advice for the best drive solution.

- Low-maintenance and reliable technology.

- Direct access to original KW Generator parts.

With the GEMA Industrial series, you get a powerful, flexible and reliable magnet system to suit the requirements of modern steel mills and mobile excavators.

Jan Kemp BV provides expert advice, professional installation and top-level service. Take contact contact us for more information, a quote or a demonstration of the GEMA Industrial in action.